In nearly every mechanical system where energy storage and force management are essential, springs play a silent but powerful role. Whether in automotive suspensions, industrial presses, aircraft mechanisms, or even consumer electronics, these coiled forms of potential energy are expected to perform with absolute precision. But their efficiency and longevity often depend on something that is both critical and widely misunderstood: torquing springs.

If you’re here asking how to torque springs, you’re probably working on something delicate—something where error could mean malfunction, safety risk, or expensive downtime. The process of torquing a spring is not just about applying force. It’s about understanding mechanical limits, material response, and controlled release or containment of energy. This guide is for engineers, technicians, hobbyists, and students who want a comprehensive, technically accurate, and up-to-date walkthrough of spring torquing—from foundational principles to advanced practice.

Why Torquing Springs Matters More Than Ever

In modern applications, torquing springs is not just a task—it’s a precision operation. The evolution of engineering tolerances, material sciences, and mechanical demands has pushed the margin for error down to fractions of a millimeter or a few Newton-meters. Whether you’re tensioning a torsion spring in a garage door or fine-tuning a spring-loaded valve in a turbine, improper torque can result in:

- Mechanical failure or fatigue

- Uneven load distribution

- Premature wear or overstress

- Safety hazards to users and operators

In critical environments such as aerospace or medical device manufacturing, incorrect spring torque can have life-or-death implications. That’s why the process requires careful understanding, not just muscle or intuition.

What Is Spring Torque?

Spring torque refers to the rotational force applied to a spring—most commonly a torsion spring—in order to achieve a specific mechanical response. Unlike compression or extension springs that deal primarily with linear motion, torsion springs store and release energy through angular displacement.

However, torque can also be relevant in coil springs during installation or Belleville washers when stacked for high-load applications. In short, if a spring rotates or applies rotational force, it involves torque.

The torque value must match the design intent of the spring—too little, and the spring fails to function; too much, and the spring may deform or fail permanently.

Key Variables in Torquing Springs

Before applying torque, it’s vital to understand the parameters influencing how torque will affect the spring’s performance:

1. Spring Material

The most common spring materials include stainless steel, music wire, phosphor bronze, and high-carbon steels. Each has a different modulus of rigidity (G), affecting how much torque it can safely handle.

2. Coil Diameter and Wire Thickness

Torque is heavily influenced by these two variables:

- Smaller wire diameter means lower torque tolerance.

- Larger coil diameter provides more leverage but increases stress on the material.

3. Number of Active Coils

More coils can distribute torque more evenly, but too many can reduce the spring’s responsiveness or increase fatigue risk.

4. Preload Requirements

Some springs are designed to be installed with a certain amount of preload—torque that exists even when the spring is at rest.

5. Operating Temperature

Springs behave differently under temperature extremes. High heat can soften material and lower the effective torque threshold.

Tools for Torquing Springs Safely and Accurately

1. Torque Wrenches

These are essential for consistent, measurable torque application. Options include:

- Beam-style: Reliable and visual.

- Click-type: Auditory feedback at target torque.

- Digital: Ideal for precision work.

2. Spring Winders

These are specifically designed for torsion springs—particularly useful for garage doors or industrial shutters.

3. Holding Fixtures and Jigs

Secure holding devices prevent injury and allow more precise force application without damaging the spring or surrounding components.

4. Digital Angle Gauges

Used for applications where torque angle (not just force) needs to be tightly controlled.

5. Safety Gear

Gloves, goggles, and guards are vital. Springs store energy and can snap or uncoil dangerously if mishandled.

Step-by-Step: How to Torque a Spring Safely

Let’s break down the procedure into a structured process. We’ll focus primarily on torsion springs, as they are most sensitive to torque application.

Step 1: Preparation

- Determine the required torque value from manufacturer specs or engineering design.

- Verify spring type, load direction, and installation orientation.

- Inspect the spring for damage, rust, or deformities.

Step 2: Secure the Spring

Use a vise or fixture to lock the spring body in place. If working with a mounted spring (like in garage doors), use winding bars of the correct length and diameter.

Step 3: Set Your Tool

Adjust your torque wrench or winding tool to the desired setting. If torque-angle is a factor, reset your angle gauge.

Step 4: Apply Torque

Turn steadily in the direction required for load. If using winding bars, rotate incrementally and insert the second bar before removing the first.

Step 5: Check Torque

Use a digital gauge or physical reference (like pointer lines) to ensure torque is at the desired level. For torsion springs, multiple full turns may be needed.

Step 6: Lock It In

Secure the spring in place using retaining screws, clips, or mounts. Double-check that torque hasn’t shifted during the fastening process.

Common Mistakes When Torquing Springs

Despite good intentions, many errors can compromise the torquing process. Here are some of the most frequent pitfalls:

- Over-torquing: This can cause permanent deformation or metal fatigue.

- Incorrect Tool Usage: Using pliers or wrenches not rated for torque leads to inconsistent results.

- Ignoring Preload: Failing to consider preload in design specs results in improper spring behavior.

- Working Alone: In high-torque setups, an assistant improves safety and accuracy.

- Improper Locking: Not securing the spring properly after torque can lead to catastrophic release.

Applications of Spring Torquing Across Industries

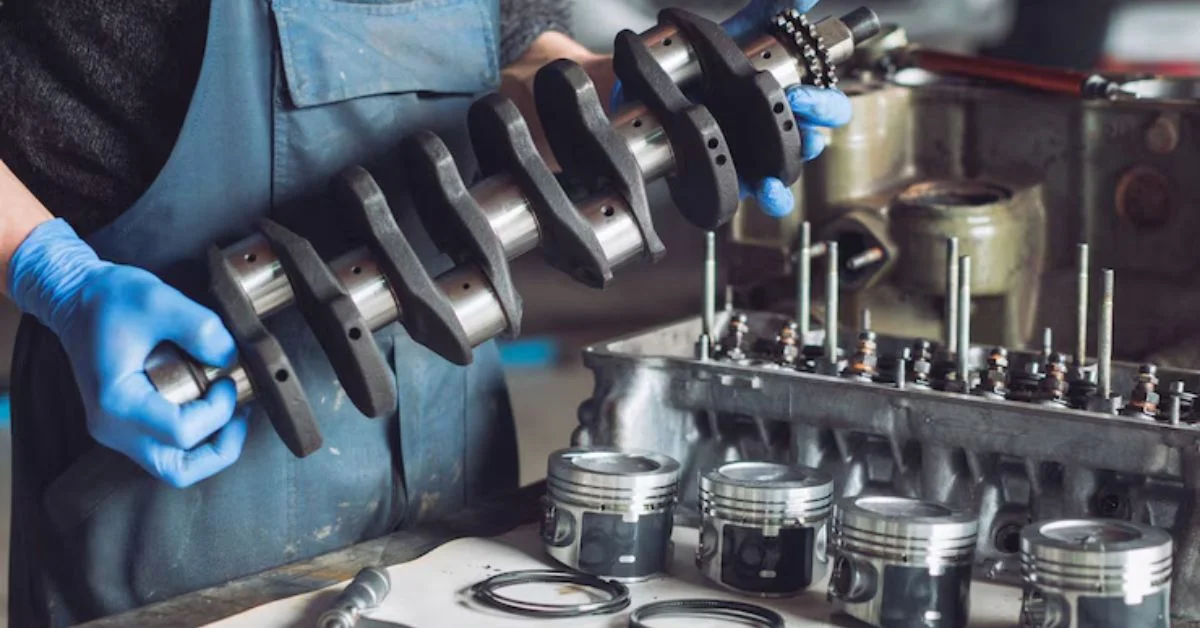

1. Automotive

Valve springs, clutch springs, and suspension springs all require precise torquing to maintain performance and driver safety.

2. Aerospace

Torque control in aircraft wing flaps, retractable landing gear, and control surfaces ensures system reliability under stress.

3. Industrial Manufacturing

Press machines and stamping equipment rely on pre-torqued springs for calibrated energy transfer.

4. Consumer Electronics

Battery holders and eject mechanisms use small torsion or spiral springs that must be torqued during assembly.

5. Medical Devices

Springs in syringes, implantable devices, or precision tools are torqued to maintain sterile performance and operational accuracy.

The Role of Engineering Standards

Various organizations provide torque guidelines for spring applications:

- SAE J157: Torsion spring specification standard

- ASTM A229/A228: Material standards for high-carbon steel springs

- ISO 26909: Specifications for disc springs with torque requirements

Following these ensures compatibility, safety, and compliance in commercial applications.

Advanced Considerations: Torque Under Dynamic Load

Static torque is just the beginning. In real-world conditions, springs often experience dynamic torque—torque that fluctuates due to movement, vibration, or load variation. Engineers must consider:

- Fatigue cycles

- Resonance frequencies

- Environmental degradation

- Lubrication and corrosion

Simulation tools like FEA (Finite Element Analysis) are often used to predict performance before physical testing.

Maintenance and Retorquing

Like any mechanical component, springs can “settle” over time, changing their torque characteristics. Retorquing schedules should be integrated into preventive maintenance plans—especially for high-load or mission-critical systems. Always re-check against the original specification after significant use.

Conclusion: Torquing Springs

Torquing springs may seem like a niche technical task, but its implications are broad and critical. It requires not only the right tools and safety precautions but also a fundamental understanding of material science, force mechanics, and operational context.

This guide has covered the full spectrum—from understanding what torque is, to how to safely apply it, to why it matters across industries. Whether you’re working on an aircraft actuator or adjusting a spring on your garage door, the principles remain the same: precision, control, and respect for the stored energy you’re managing.

By following best practices and avoiding common mistakes, you can ensure your springs deliver consistent performance, long life, and above all—safety.

FAQs: Torquing Springs

1. What is the best tool for torquing a torsion spring?

A torque wrench or a spring winding bar, depending on the spring size and application. Always use tools rated for your required torque.

2. Can I reuse a spring after over-torquing it?

Generally no. Over-torqued springs may have microfractures or permanent deformation. Replace them to avoid mechanical failure.

3. How do I know the correct torque value for my spring?

Refer to manufacturer specifications or engineering design documents. Torque values depend on material, wire diameter, and intended use.

4. Do all springs require torque adjustment?

No. Only springs that operate via rotational force (like torsion springs) require torquing. Compression and extension springs rely on linear force.

5. What safety precautions should I take when torquing springs?

Wear gloves and goggles, secure the spring in a jig or vise, and never work alone in high-tension situations. Always release torque slowly and evenly.

For more information, click here.